PETCOKE

Also know as petroleum cokepetcoke is produced through the refining of petroleum and contains a high proportion of carbon. It is a form of solid carbon produced by means of heat decomposition and polymerization of heavy liquid hydrocarbons derived from the refining of crude. There are many commercial varieties of petcoke with different physical and chemical characteristics being used in different industrial applications, depending on the method of industrial production used to obtain it. The most common production methods used are:

Green delayed coking

a method of cracking in which the carbonization reactions involve dehydrogenization, restructuring and polymerization. The working temperature fluctuates between 480ºC and 500ºC and a complete production cycle takes at least 16 hours.

Fluid coking

is a continuous process of pulverization at high temperatures on a fluid surface in which the coke particles are maintained at a pressure of between 20-40 psi and 500ºC. These feed vapors are subjected to heat cracking while they are being deposited, forming a liquid film on reheated coke particles, finally becoming nucleant agents. Thus, the particles grow in layers until they can finally be removed. Finally, another layer of nucleant coke particles is added to the system.

| COMPOSITION | |

|---|---|

| Moisture | 10% |

| Ash | 0.8% max. |

| Volatiles | 8/14% |

| Sulfur | 2a7% |

| Fixed carbon | 80% |

| Pcs kcal/kg | 7800 |

| Hgi | 30-90 |

| SIZE | INDUSTRY |

|---|---|

| 0x10mm | Lime, ceramics ,cement, chemical, suger, metal, paper, alloys, themal, furnace and calcined (clay,magnesite,limestone), asphalt/isolators |

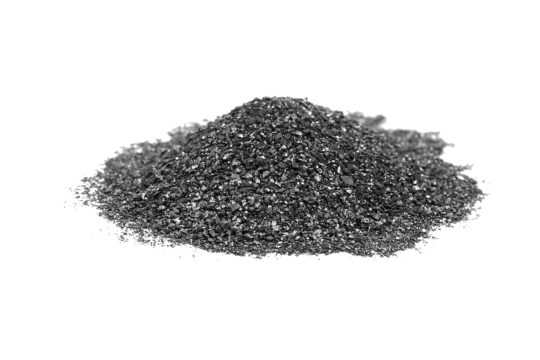

MICRONIZED PETROLEUM COKE (PETCOKE)

Micronized petcoke is an evolved version of petroleum coke. Thanks to the micronization system, a process developed by our organisation more than 10 years ago, the coke is provided with the optimal properties for use.

Broadly speaking, the process consists of drying and grinding the coke down to a size of 90 to 500 microns. This improves the fuel’s properties, allowing for better combustion in the furnace and reducing unburned coke.

These properties mainly revolve around homogenising the product in size and moisture content and increasing its calorific value, thus allowing for greater stability in the combustion processes for which it is used.

In addition, its form provides benefits over liquid or gas fuels in terms of supply and storage.

| COMPOSITION | |

|---|---|

| Moisture | < 0.5% |

| Ash | 0.8% max. |

| Volatiles | 14% |

| Sulfur | 2a7% |

| Fixed carbon | 88% |

| Pcs kcal/kg | 8400 |

| SIZE | INDUSTRY |

|---|---|

| 90% less than 100 microns | Lime, ceramics, cement, chemical products, sugar, metal, paper, alloys, thermal, furnaces and calciners (clay, magnesite, limestone), asphalt/isolators. |

THERMAL COAL

Due to its content in volatiles, thermal coal burns consistently and is therefore mainly used in industries and furnaces that require stable combustion.

We also distribute other types of coal:

- Washed coal with low ash content:

2% maximum. - Coal with low Al content:

1% maximum.

| COMPOSITION | |

|---|---|

| Moisture | 7-14% |

| Ash | 2-15% |

| Volatiles | 22-37% |

| Sulfur | 0.3-1% |

| SIZE | |

|---|---|

| 0x6 mm | |

| 6×10 mm | |

| 10×25 mm | |

| 25×45 mm | |

| > 45 mm |

ANTHRACITE

This mineral is extracted directly from the mines and contains a high proportion of carbon, low volatility and low sulfur content, which give it excellent properties for use in reduction processes or as a source of energy.

Depending on the origin of the mining basin, there are three types of anthracite:

Low volatiles content

This type of anthracite is especially suitable for carbon/reduction contribution, such as steel, metal and chemicals

Medium volatile content

Particularly indicated for domestic use, both for its ash content and its higher volatile level, although it can be used in industry.

High content of volatile

Particularly indicated for domestic use.

| COMPOSITION | |

|---|---|

| Moisture | 10% |

| Ash | 2-10% |

| Volatiles | 2-3% |

| Sulfur | 1% max |

| Fixed carbon | 88% |

| Pcs kcal/kg | 7000 |

| COMPOSITION | |

|---|---|

| Moisture | 8% |

| Ash | 5-10% |

| Volatiles | 5-6% |

| Sulfur | 1% max |

| Fixed carbon | 84% |

| Pcs kcal/kg | 7400 |

| COMPOSITION | |

|---|---|

| Moisture | 8% |

| Ash | 12% max. |

| Volatiles | 8-9% |

| Sulfur | 0,50% max |

| Fixed carbon | 82% min. |

| Pcs kcal/kg | 7300 min. |

| SIZE | INDUSTRY |

|---|---|

| 0x10mm | Ferroalloys, steel, metal, lime kiln, castings, household, sugar, chemical. |

FOAMING AGENTS

This type of solid fuel is designed especially for use in the steel sector as a contributor of fixed carbon, slag foaming agents and to fight dross.

Anthracite

On the basis of anthracites with a low volatile content and high carbon content, we undertake a process of drying, micronizing and screening for supply to the steel industry.

This material is special for its low humidity content and high fixed carbon content.

| SIZE | |

|---|---|

| de 0 a 1 mm | |

| de 1 a 3 mm | |

| > 3 mm |

Calcined Petroleum Coke

The process of calcined petcoke yields a product with a very high fixed carbon content (99%) and with exceptionally low levels of sulfur, volatiles and nitrogen.

This product is especially indicated for special steels that require high contributions of carbon during the production process.

Currently, we present this product in the following sizes:

| SIZE | |

|---|---|

| de 0 a 1 mm | |

| de 1 a 3 mm |

METCOKE

The metcoke is produced in coking furnaces and its main purpose is combustion in reduction processes. The main composition of metcoke is as follows: fixed carbon, sulfur, nitrogen, hydrogen, oxygen, ash and volatile material. Its final composition depends on the duration of the distilling process and the composition of the coking coal used.

| COMPOSITION | |

|---|---|

| Moisture | 10% |

| Ash | 12% max. |

| Volatiles | 1,5% |

| Sulfur | < 1% |

| Fixed carbon | 80% min. |

| Pcs kcal/kg | 7800 min. |

| Hgi | 30-90 |

| SIZE | INDUSTRY |

|---|---|

| 0x10 mm | Iron foundires, meta, steel, chemicals, lead foundries, ferro-alloys, production of stone wool and other insulation materials. |

| 10×25 mm | |

| 30×90 mm | |

| 40×60 mm | |

| 90×250 mm |

BIOMASS

Biomass is the organic material used as an alternative energy source to fossil fuels. There are several types of biomass derived from forest residues and agricultural residues, such as wood pellets, olive and fruit by-products (pomace, treated bones, shells and flours), products that are processed to obtain the highest energy efficiency from them and without negative impact on our environment

Being a renewable energy, it is an inexhaustible resource.

It comes from natural agricultural surpluses that are recycled.

It does not have a significant environmental impact (neutral CO2).

Helps reduce the risk of forest fires.

Wood pellets for domestic use

The wood pellet with ENPlus A1 quality certificate is a type of biomass or ecological energy raw material produced with 100% pine. It does not contain additives. Therefore, in its combustion there is no presence of harmful emissions.

Olive stones

The olive-oil mill bone is obtained by separating the bone from the olive pulp. The separation is usually carried out in olive-oil mills by physical procedures, being used as energy raw material in different phases of olive processing.

| SIZE | |

|---|---|

| 6 mm |

| COMPOSITION | |

|---|---|

| Moisture | < 10% |

| Ash | 0.7% |

| Apparent density | > 600 kg/m³ |

| Mechanical durability | > 97,5% |

| Sulfur | < 0,03% |

| PCI kcal/kg | > 4100 |

| Fines content (< 3,15 mm) |

< 1% |

| SIZE | |

|---|---|

| < 5mm |

| COMPOSITION | |

|---|---|

| Moisture | 17 – 25% |

| Ash | 0.5 – 2.5% |

| Volatiles | 60 – 85% |

| Sulfur | < 30% |

| Fixed carbon | < 0,15% |

| Pcs kcal/kg | 3.900 |

| Oil content | < 3% |

Extracted pomace

The extracted pomace pellets are obtained by granulation of the extracted pomace, previously obtained as a secondary result of the extraction of the oil from the olive.

Grape seed flour

Grape granule flour is obtained by grinding the seed or bone of the grape once the oil has been extracted. The resulting biomass is a small solid particle.

| SIZE | |

|---|---|

| < 10mm |

| COMPOSITION | |

|---|---|

| Moisture | 8 – 15% |

| Ash | 7 – 9% |

| Volatiles | 50 – 80% |

| Sulfur | < 0,20% |

| Fixed carbon | < 40% |

| Pcs kcal/kg | > 4.000 |

| SIZE | |

|---|---|

| < 10mm |

| COMPOSITION | |

|---|---|

| Moisture | 9 – 20% |

| Ash | 8% max. |

| Volatiles | 45 – 70% |

| Sulfur | < 0,20% |

| Fixed carbon | < 40% |

| Pcs kcal/kg | 3500 - 4300 min. |

Dry olive stone

The olive-oil mill bone is obtained by separating the bone from the olive pulp. The separation is usually carried out in olive-oil mills by physical procedures, being used as fuel in different phases of olive processing. Subsequently, the bone is dried, leaving a solid substance with humidity below 15%.

Extracted pomace

The pomace is the byproduct generated in olive-oil mills during the process of obtaining olive oil. After being dehydrated and extracted (by chemical extraction using hexane) olive pomace is obtained.

| SIZE | |

|---|---|

| < 5mm |

| COMPOSITION | |

|---|---|

| Moisture | 6 – 15% |

| Ash | 0.5 – 2.5% |

| Volatiles | 70 – 80% |

| Sulfur | < 0,15% |

| Fixed carbon | < 30% |

| Pcs kcal/kg | 4050 |

| SIZE | |

|---|---|

| 0 – 5 mm |

| COMPOSITION | |

|---|---|

| Moisture | 8 – 15% |

| Ash | 7 – 9% |

| Volatiles | 50 – 80% |

| Fixed carbon | < 40% |

| Pcs kcal/kg | > 3850 |

| Oil content | < 3% |

Almond shell

Its biomass is obtained in almond shelling machines through physical separation of the almond shell.

Wood chips

Chips from different varieties of ligneous trees.

| SIZE | |

|---|---|

| <35mm |

| COMPOSITION | |

|---|---|

| Moisture | 6-15% |

| Ash | 0.5-2% |

| Volatiles | 70-85% |

| Sulfur | < 0,15% |

| Pcs kcal/kg | 4000 – 4500 |

Grape seed flour

Grape seed ground after extraction of oil.

In GME ENERGÍA we are in continuous evolution, looking for and developing products specially designed for our customers, being in turn, as respectful as possible with our environment.

* Immediate data analysis of each of the products are not contractual data, subject to possible variations depending on the time that the product has been exposed to weathering and transport conditions.